Well for all intents and purposes, the metal work on the body is complete.

Moving onto the accessory body parts next. Keep on truckin'!

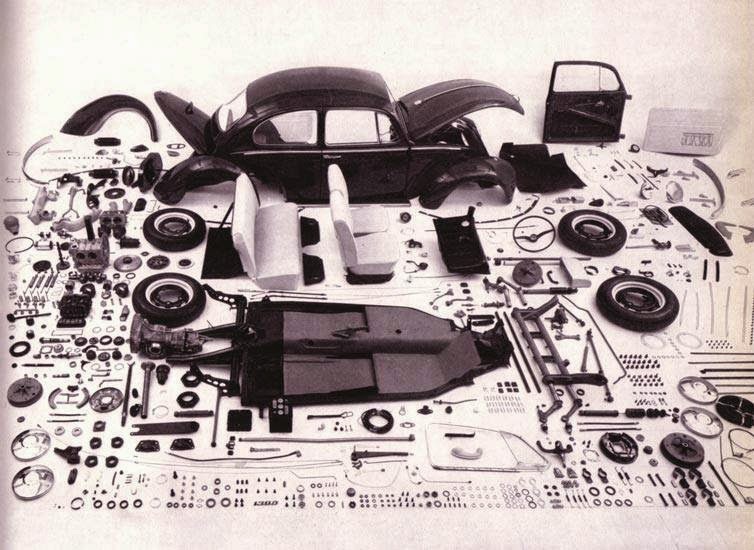

If only the car was ready to assemble like this!

Wednesday, December 10, 2014

Tuesday, December 2, 2014

Day 113

With work and the holidays progress has slowed.

Today I did get back at it and worked on the front apron again.

I mocked everything up and got it all situated. There will still be some more adjusting before welding.

I also found out the minor work I did on the passenger side hasn't fixed the little bump that Louise got sometime in her previous life. The front quarter panel is smoothed out, but there is still a fairly large gap on the passenger side. I need to sort this out before I can move forward. Blah!

So, off to do some research on how to fix it and hopefully more progress!

Today I did get back at it and worked on the front apron again.

I mocked everything up and got it all situated. There will still be some more adjusting before welding.

I also found out the minor work I did on the passenger side hasn't fixed the little bump that Louise got sometime in her previous life. The front quarter panel is smoothed out, but there is still a fairly large gap on the passenger side. I need to sort this out before I can move forward. Blah!

|

| The good side. |

|

| Too much on the bottom part of the hood. |

Monday, November 17, 2014

Day 112

Been a few days since I worked on the bug.

Today I took the "oil canning effect" out of my driver's side front quarter panel. It is named after that sound that an old metal oil can use to make when you squeeze the sides. After welding in the A pillar, it had been heated up to a point where the panel started to flex. I used my stud welder and heated it up in a concentric circle and then quickly cooled it with a wet towel. Doing this causes the metal to shrink! And the oil canning effect goes away.

I also took care of the passenger front quarter. This is where that small collision damage was. With some hammer and dolly-ing around the front bumper mount that area was relatively easy to fix. However, the area that had crinkled was behind another panel and I wasn't able to get behind it. So I had to weld studs to it (stud welder used in previous fix, multi-task!) and then a slide hammer which grabs the stud and then a weight is used to pull back on it to get the metal out of it's concave shape.

Although it looks pretty rough in the picture, a light coat of metal filler and it will like new.

Now I need to weld the front apron and spare tire tray in. Then onto some of the body parts!

Today I took the "oil canning effect" out of my driver's side front quarter panel. It is named after that sound that an old metal oil can use to make when you squeeze the sides. After welding in the A pillar, it had been heated up to a point where the panel started to flex. I used my stud welder and heated it up in a concentric circle and then quickly cooled it with a wet towel. Doing this causes the metal to shrink! And the oil canning effect goes away.

I also took care of the passenger front quarter. This is where that small collision damage was. With some hammer and dolly-ing around the front bumper mount that area was relatively easy to fix. However, the area that had crinkled was behind another panel and I wasn't able to get behind it. So I had to weld studs to it (stud welder used in previous fix, multi-task!) and then a slide hammer which grabs the stud and then a weight is used to pull back on it to get the metal out of it's concave shape.

|

| In this pic, you can sort of see the front passenger side quarter damage. |

|

| After panel beating the front part, I welded the studs onto the carb to pull the dent out. |

| Slide hammer. |

|

Now I need to weld the front apron and spare tire tray in. Then onto some of the body parts!

Monday, November 10, 2014

Day 110 & 111

Well today I welded in the master cylinder shelf area. It was quite a pain, with several burn-throughs and some fitment issues.

But it's done!

A few days ago I prepped the front apron attach area by grinding down all the spot weld holes in the previous post. And yesterday I patched all the holes on the front quarter panels where the spare tire well attaches.

I'd like to get the front apron/spare tire well on and taken care of. After that is complete...on to metal work on the various body parts. Fenders, doors, hood, decklid, and some welding on the seats.

Moving along...

|

| The top one is too hole-y :) |

|

| Prepped. |

|

| Welded, ground, primered. |

But it's done!

A few days ago I prepped the front apron attach area by grinding down all the spot weld holes in the previous post. And yesterday I patched all the holes on the front quarter panels where the spare tire well attaches.

I'd like to get the front apron/spare tire well on and taken care of. After that is complete...on to metal work on the various body parts. Fenders, doors, hood, decklid, and some welding on the seats.

Moving along...

Tuesday, November 4, 2014

Day 109

I've had quite a few days off, but after some visitors and my thumb injury I didn't get into it as much as I had hoped.

The weather has also cooled down significantly. So much so, that I had to use my garage heater today! And also having trouble with the pan starting since my manual choke isn't hooked up. May have to rig something up to make that work.

Anyway, today I did a little bit of metal bumping on the front apron. I also removed the old, rotten spare tire well from the front apron. Then I welded it up, will grind it smooth tomorrow.

Here is the accident damage I talked about last post that needs repaired, passenger side. You can also see what the media blaster didn't get and what that means for the rest of the car! Even though it has been blasted clean there are still spots that I will just never be able to get. :)

Will do some metal prep on the front area of the car and replace the master cylinder shelf area...then reassemble!

The weather has also cooled down significantly. So much so, that I had to use my garage heater today! And also having trouble with the pan starting since my manual choke isn't hooked up. May have to rig something up to make that work.

Anyway, today I did a little bit of metal bumping on the front apron. I also removed the old, rotten spare tire well from the front apron. Then I welded it up, will grind it smooth tomorrow.

Here is the accident damage I talked about last post that needs repaired, passenger side. You can also see what the media blaster didn't get and what that means for the rest of the car! Even though it has been blasted clean there are still spots that I will just never be able to get. :)

|

|

| Inside of the front apron. |

|

| Some more work to do on the bottom lip. |

|

| Will grind these tomorrow. |

Will do some metal prep on the front area of the car and replace the master cylinder shelf area...then reassemble!

Friday, October 31, 2014

Day 108

Welp, today was an interesting day. I really didn't get much done but it took a few hours to do it...if that makes sense?

I needed to remove the front apron which required the drilling out of probably 50 spot welds. I have a special tool called a spot weld cutter that is like a miniature hole saw. It makes easy work of this job.

Results.

Unfortunately, about half way through I had the biggest accident I've had with this entire project involving myself. I've had cuts, scrapes, bruises, 6 month long splinters, weld burns, etc. etc.

But none bled as badly as this and had me as worried. The spot weld cutter slipped and started working its magic on my left thumb. Blood on the bug body, so now I can say I have blood, sweat, money, and it freakin' hurt... so tears into this car!

So needless to say, off to urgent care I went for a tetanus booster (probably will need that in the future anyway) and some antibiotics 4 times daily.

I actually cut my thumb about half way through the project and decided to finish it so I could get the front apron off :)

Here's the pictures of the driver's side A pillar. Will need some filler work, but not too bad.

And a nice picture from work.

This front apron is going to take quite a while. I need to replace the master cylinder shelf, repair the accident damage on the left side of the car, prep the front area, and then mount the new spare tire well and re-attach the front apron.

I needed to remove the front apron which required the drilling out of probably 50 spot welds. I have a special tool called a spot weld cutter that is like a miniature hole saw. It makes easy work of this job.

| Tool. |

Results.

|

| Nose job! |

|

| Left side has some accident damage, discussed in earlier posts? |

|

| This piece needed to be removed so I could replace the rusted bottom seen here. |

|

| I still have to drill out the spot welds seen at the top of this piece. The front apron and spare tire well are two different pieces entirely. |

But none bled as badly as this and had me as worried. The spot weld cutter slipped and started working its magic on my left thumb. Blood on the bug body, so now I can say I have blood, sweat, money, and it freakin' hurt... so tears into this car!

|

| What was left of my thumb stuck in the drill bit, it was white, but weird lighting in this picture. |

So needless to say, off to urgent care I went for a tetanus booster (probably will need that in the future anyway) and some antibiotics 4 times daily.

I actually cut my thumb about half way through the project and decided to finish it so I could get the front apron off :)

Here's the pictures of the driver's side A pillar. Will need some filler work, but not too bad.

And a nice picture from work.

This front apron is going to take quite a while. I need to replace the master cylinder shelf, repair the accident damage on the left side of the car, prep the front area, and then mount the new spare tire well and re-attach the front apron.

Wednesday, October 29, 2014

Day 107

Today I finished the driver's side A pillar. It took quite a bit longer than the passenger side because it was a full wrap-around piece. But, it's done! Pictures later.

Front tire well and master cylinder shelf next. :)

Front tire well and master cylinder shelf next. :)

Monday, October 6, 2014

Day 106

Alright, so long awaited...here are the pictures I promised in the last post. The repaired trunk area and pop out windows.

Today, I worked on the passenger side A pillar area. This one was the one that had the least amount of damage. In case you don't remember, here's what it looked like before.

Well, I can say that after 8 hours (!!) I finally got this area repaired. Of course it was a bit more taxing than I expected...but so has everything else!

So, that was the A pillar. I still have the driver's side to go. Will do that next. Then I'll move onto the nose and will remove the front apron and repair the spare tire well and master cylinder reservoir shelf.

BONUS MATERIAL!

Vegas has an annual Bug show and I went to check it out this past weekend. Saw some cool cars, got some ideas, what to do and not!

See ya next time!

|

| No rust! |

|

| Front driver's side tire well repair. |

|

| Can you feel the breeze? |

|

| Swiss cheese. |

|

| More holes. |

|

| And some minor patch areas. |

|

| Cut and replace. |

|

| Had to remove the carpet hold down rail in order to get to the A pillar. |

|

| Not too bad inside. |

|

| Repaired! |

|

| Good as new! (sort of) |

|

| Turned out well. |

BONUS MATERIAL!

Vegas has an annual Bug show and I went to check it out this past weekend. Saw some cool cars, got some ideas, what to do and not!

|

| I think this is Diamond Grey. The license plate is funny too ;) |

|

| What a very original engine should look like. The spark plug wires are not stock but a nice vintage touch. |

See ya next time!

Subscribe to:

Comments (Atom)